MORINGA OLEIFERA (MO) SEED SHELL BASED ADSORBENT FOR POTENTIAL CO2 CAPTURE: A CHARACTERIZATION STUDY

Main Article Content

Abstract

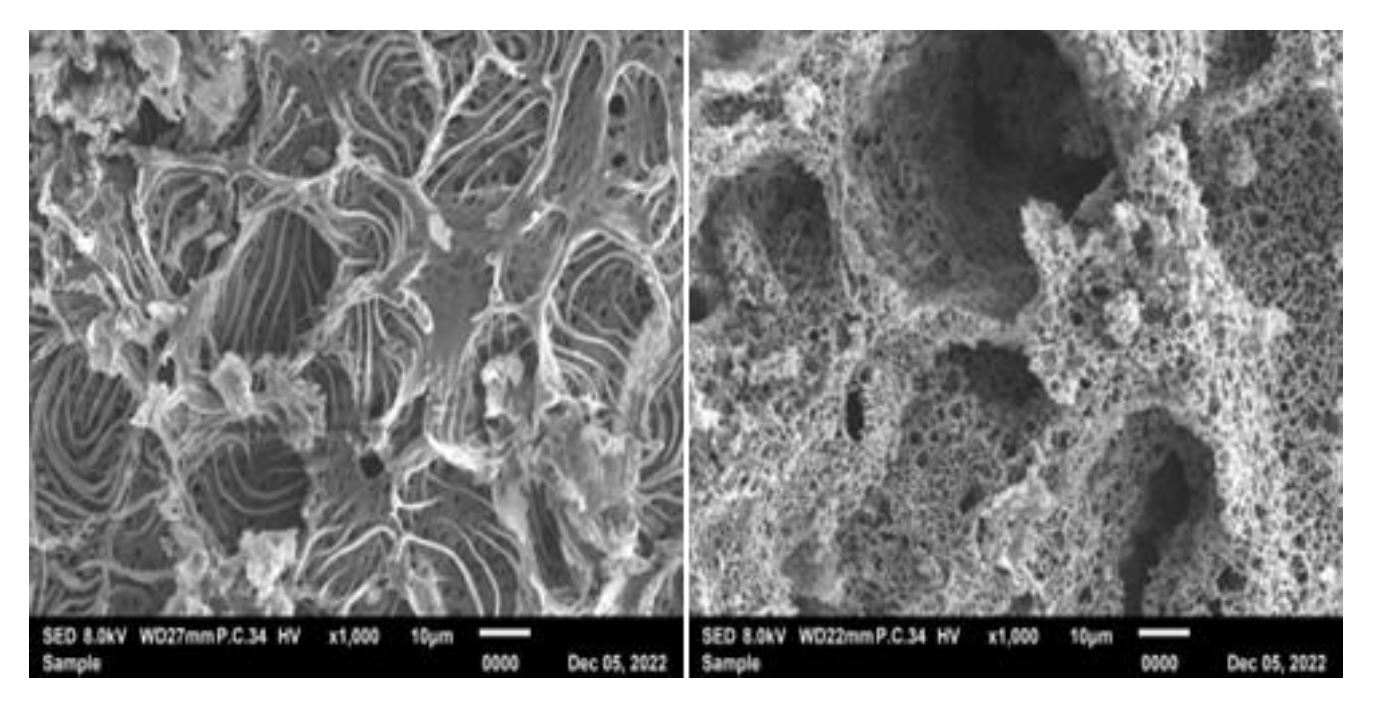

This study characterizes activated carbon synthesized from Moringa oleifera (MO) seed husk with a greener activating agent, namely sodium carbonate, (Na2CO3) compared to traditional activating agent, potassium hydroxide (KOH). Synthesized in a conventional tube furnace with nitrogen supply, the resulting activated carbon after cooling and washing, were characterized for Brunauer-Emmett-Teller (BET), Fourier-Transform Infrared Spectroscopy (FTIR), X-ray Diffraction (XRD) and Scanning Electron Microscope (SEM) analyses and compared with that produced with KOH activation. Although fewer and larger mesoporous activated carbon with smaller BET surface area (18.4659 m²/g) were formed with Na2CO3 activation), compared to that of KOH activation (235.6034 m²/g), this study highlights the ability and potential of the greener activating agent (Na2CO3) to utilize biomass waste and successfully produce activated carbon with minimum environmental hazards. The synthesized adsorbent can be explored for CO2 capture applications in future studies.

Downloads

Article Details

Transfer of Copyrights

- In the event of publication of the manuscript entitled [INSERT MANUSCRIPT TITLE AND REF NO.] in the Malaysian Journal of Science, I hereby transfer copyrights of the manuscript title, abstract and contents to the Malaysian Journal of Science and the Faculty of Science, University of Malaya (as the publisher) for the full legal term of copyright and any renewals thereof throughout the world in any format, and any media for communication.

Conditions of Publication

- I hereby state that this manuscript to be published is an original work, unpublished in any form prior and I have obtained the necessary permission for the reproduction (or am the owner) of any images, illustrations, tables, charts, figures, maps, photographs and other visual materials of whom the copyrights is owned by a third party.

- This manuscript contains no statements that are contradictory to the relevant local and international laws or that infringes on the rights of others.

- I agree to indemnify the Malaysian Journal of Science and the Faculty of Science, University of Malaya (as the publisher) in the event of any claims that arise in regards to the above conditions and assume full liability on the published manuscript.

Reviewer’s Responsibilities

- Reviewers must treat the manuscripts received for reviewing process as confidential. It must not be shown or discussed with others without the authorization from the editor of MJS.

- Reviewers assigned must not have conflicts of interest with respect to the original work, the authors of the article or the research funding.

- Reviewers should judge or evaluate the manuscripts objective as possible. The feedback from the reviewers should be express clearly with supporting arguments.

- If the assigned reviewer considers themselves not able to complete the review of the manuscript, they must communicate with the editor, so that the manuscript could be sent to another suitable reviewer.

Copyright: Rights of the Author(s)

- Effective 2007, it will become the policy of the Malaysian Journal of Science (published by the Faculty of Science, University of Malaya) to obtain copyrights of all manuscripts published. This is to facilitate:

- Protection against copyright infringement of the manuscript through copyright breaches or piracy.

- Timely handling of reproduction requests from authorized third parties that are addressed directly to the Faculty of Science, University of Malaya.

- As the author, you may publish the fore-mentioned manuscript, whole or any part thereof, provided acknowledgement regarding copyright notice and reference to first publication in the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers) are given. You may produce copies of your manuscript, whole or any part thereof, for teaching purposes or to be provided, on individual basis, to fellow researchers.

- You may include the fore-mentioned manuscript, whole or any part thereof, electronically on a secure network at your affiliated institution, provided acknowledgement regarding copyright notice and reference to first publication in the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers) are given.

- You may include the fore-mentioned manuscript, whole or any part thereof, on the World Wide Web, provided acknowledgement regarding copyright notice and reference to first publication in the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers) are given.

- In the event that your manuscript, whole or any part thereof, has been requested to be reproduced, for any purpose or in any form approved by the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers), you will be informed. It is requested that any changes to your contact details (especially e-mail addresses) are made known.

Copyright: Role and responsibility of the Author(s)

- In the event of the manuscript to be published in the Malaysian Journal of Science contains materials copyrighted to others prior, it is the responsibility of current author(s) to obtain written permission from the copyright owner or owners.

- This written permission should be submitted with the proof-copy of the manuscript to be published in the Malaysian Journal of Science

Licensing Policy

Malaysian Journal of Science is an open-access journal that follows the Creative Commons Attribution-Non-commercial 4.0 International License (CC BY-NC 4.0)

CC BY – NC 4.0: Under this licence, the reusers to distribute, remix, alter, and build upon the content in any media or format for non-commercial purposes only, as long as proper acknowledgement is given to the authors of the original work. Please take the time to read the whole licence agreement (https://creativecommons.org/licenses/by-nc/4.0/legalcode ).

References

Abuelnoor N., AlHajaj, A., Khaleel M., Vega L. F. & Abu-Zahra M R M. (2021). Activated carbons from biomass-based sources for CO2 capture applications. Chemosphere, 282(March), 131111, https://doi.org/10.1016/j.chemosphere.2021.131111.

Azmi A. A. & Aziz M. A. A. (2019). Mesoporous adsorbent for CO2 capture application under mild condition: A review. Journal of Environmental Chemical Engineering, 7(2), 103022, https://doi.org/10.1016/j.jece.2019.103022.

González-García P. (2018). Activated carbon from lignocellulosics precursors: A review of the synthesis methods, characterization techniques and applications. Renewable and Sustainable Energy Reviews, 82(August 2017), 1393–1414, https://doi.org/10.1016/j.rser.2017.04.117.

Jawad A. H. & Abdulhameed A. S. (2020). Statistical modeling of methylene blue dye adsorption by high surface area mesoporous activated carbon from bamboo chip using KOH-assisted thermal activation. Energy, Ecology and Environment, 5(6), 456–469, https://doi.org/10.1007/s40974-020-00177-z.

Khalfaoui A., Mahfouf E., Derbal K., Boukhaloua S., Chahbouni B. & Bouchareb R. (2022). Uptake of Methyl Red dye from aqueous solution using activated carbons prepared from Moringa Oleifera shells. 4(September), https://doi.org/10.1016/j.clce.2022.100069.

Nedjai R., Alkhatib M. F. R., Alam M. Z. & Kabbashi N. A. (2021). Adsorption Of Methylene Blue Onto Activated Carbon Developed From Baobab Fruit Shell By Chemical Activation: Kinetic Equilibrium Studies. IIUM Engineering Journal, 22(2), 31–49, https://doi.org/10.31436/iiumej.v22i2.1682.

Nguyen T. H., Kim S., Yoon M. & Bae T. H. (2016). Hierarchical Zeolites with Amine-Functionalized Mesoporous Domains for Carbon Dioxide Capture. ChemSusChem, 9(5), 455–461, https://doi.org/10.1002/cssc.201600004.

Prakash M. O., Raghavendra G., Ojha S. & Panchal M. (2020). Characterization of porous activated carbon prepared from arhar stalks by single step chemical activation method. Materials Today: Proceedings, 39(xxxx), 1476–1481, https://doi.org/10.1016/j.matpr.2020.05.370.

Prahas D., Kartika Y., Indraswati N. & Ismadji S. (2008). Activated carbon from jackfruit peel waste by H3PO4 chemical activation: Pore structure and surface chemistry characterization. Chemical Engineering Journal, 140(1–3), 32–42, https://doi.org/10.1016/j.cej.2007.08.032.

Raji Y., Nadi A., Mechnou I., Saadouni M., Cherkaoui O. & Zyade S. (2023). High adsorption capacities of crystal violet dye by low-cost activated carbon prepared from Moroccan Moringa oleifera wastes: Characterization, adsorption and mechanism study. Diamond and Related Materials, 135(February), 109834, https://doi.org/10.1016/j.diamond.2023.109834.

Santos T. M., de Jesus F. A., da Silva G. F. & Pontes L. A. M. (2020). Synthesis of activated carbon from oleifera moringa for removal of oils and greases from the produced water. Environmental Nanotechnology, Monitoring and Management, 14(August), https://doi.org/10.1016/j.enmm.2020.100357.

Serafin J., Ouzzine M., Cruz O. F., Sreńscek-Nazzal J., Campello Gómez I., Azar F. Z., Rey Mafull C. A., Hotza D. & Rambo C. R. (2021). Conversion of fruit waste-derived biomass to highly microporous activated carbon for enhanced CO2 capture. Waste Management, 136(October), 273–282, https://doi.org/10.1016/j.wasman.2021.10.025.

Sevilla M., Díez N. & Fuertes A. B. (2021). More Sustainable Chemical Activation Strategies for the Production of Porous Carbons. ChemSusChem, 14(1), 94–117, https://doi.org/10.1002/cssc.202001838.

Yamaguchi N. U., Cusioli L. F., Quesada H. B., Camargo Ferreira M. E., Fagundes-Klen M. R., Salcedo Vieira A. M., Gomes R. G., Vieira M. F. & Bergamasco R. (2021). A review of Moringa oleifera seeds in water treatment: Trends and future challenges. Process Safety and Environmental Protection, 147(September), 405–420, https://doi.org/10.1016/j.psep.2020.09.044.

Varma R. S. (2019). Biomass-Derived Renewable Carbonaceous Materials for Sustainable Chemical and Environmental Applications. ACS Sustainable Chemistry and Engineering, 7(7), 6458–6470, https://doi.org/10.1021/acssuschemeng.8b06550.

Vunain E. & Biswick T. (2019). Adsorptive removal of methylene blue from aqueous solution on activated carbon prepared from Malawian baobab fruit shell wastes: Equilibrium, kinetics and thermodynamic studies. Separation Science and Technology (Philadelphia), 54(1), 27–41, https://doi.org/10.1080/01496395.2018.1504794.

Zhang S., Zheng M., Tang Y., Zang R., Zhang X., Huang X., Chen Y., Yamauchi Y., Kaskel S. & Pang H. (2022). Understanding Synthesis–Structure–Performance Correlations of Nanoarchitectured Activated Carbons for Electrochemical Applications and Carbon Capture. Advanced Functional Materials, 32, https://doi.org/10.1002/adfm.202204714.